NEVA/MAGIS: BELT TENSION ON THE CARRIAGES!

links: https://clubdagoma.popsell.com/max-38805/371666

https://clubdagoma.popsell.com/max-38805/372495

As you've seen lately, I've put out a Neva/Magis top for belt tension.

It's a good idea. So good that it quickly became a problem:

HOW DO YOU PRINT IT WHEN YOU ONLY HAVE ONE NEVA/MAGIS?

Therefore, an alternative solution is needed to allow as many people as possible to benefit from additional settings.

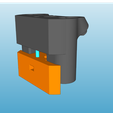

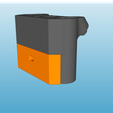

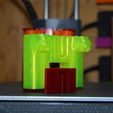

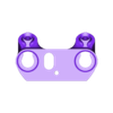

So I designed carriages in 2 parts (one fixed, the other mobile) to allow the adjustment of the belts.

The adjustment page via the carriages is 7 to 10mm of tension depending on the type and direction of the brake nut. This is much more than necessary.

The STLs are already turned in the printing direction, no media required, it's ready to print! :)

EQUIPMENT:

You'll have to:

ASSEMBLY:

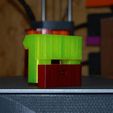

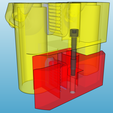

At first, before dismantling your machine, but after printing the carriages, you will have to mark the belt ends coming out of the top of the carriages (see photo).

This to keep the right length between the carriage and the top, but also the top to the limit sensor (white or silver markings on the belts).

Once this has been done, you can proceed with the removal of the belts, top, bearings and ball joints.

These are to be put back on the new carts right away.

Insert the M3 lock nut into the small square slot in the movable part of the carriage, then insert the screw.

As soon as the screw starts to engage in the nut, do not tighten any more!

You must leave room for adjustment of the tension.

Once everything is assembled and the carriages put back on the machine, start putting the belts back on from the top via the mark you made beforehand.

Then do the same for the lower part, trying to tighten the belts as much as possible anyway, but without forcing.

Once that's done, we'll proceed with the tension.

THE SETTINGS:

Put the carriages halfway on the bars of the machine (all 3 at about the same level).

Start the tensioning of the first belt by screwing the moving part of the carriage.

When it seems tight, move on to the next one.

On the free belt that passes through the carriage via the oblong passage, pinch the belt as you would pinch a guitar string to make it resonate.

Do the same with the others.

They must emit a low, muffled sound. But maybe not the same sound.

With the screws, you have to tighten the 3 belts so that they all emit the same low and muffled sound.

If you're a musician, you've understood that it's all about tuning the machine!

The use of a tuner (or a tuning application) is possible.

/!\

CAUTION: The belts must be taut, but neither too much nor too little.

The method I use is not necessarily the best, but it works for me.

Feel free to do as you see fit afterwards.

/!\

Once the three straps "sing" the same note, it's over!

you will need to redo an initial calibration before starting a printout.

CAUTION: The belts must be taut, but neither too much nor too little.

The method I use is not necessarily the best, but it works for me.

Feel free to do as you see fit afterwards.

WARNING:

After a few prints, you'll have to check that the tension is still good.

Adjust if necessary.

This custom is a personal project, which took me a lot of time to conceive and realize, that I offer you for free, all under a relatively open license.

So I would not make a custom modification (hence the choice of the license)

However, if you are satisfied and want to support me, you can offer me a coffee ;)

https://www.paypal.com/donate?hosted_button_id=ECW6TFMMYQZJW

THANK YOU:

I would like to thank Olivier S. from Club Dagoma, for testing one of the first prototypes to help me spot the good and bad approaches.

But also those who follow my projects and bring me their ideas/improvements.

/https://fbi.cults3d.com/uploaders/13771861/illustration-file/2898de77-896b-4ccb-a568-aa946f4fd218/0003.png)