Fighting Climate Change, an Efficient Bearing and Planetary gear - a new geometry claiming the least resistance and greatest axial load capacity of any comparably sized gear or bearing.

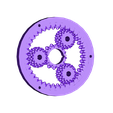

As most 3D printing entusiasts know, There are no innovative and practical bearing designs for 3D printing. What makers need is a totally new and novel 3D printable bearing means which can be really useful. Here is a new design by fractalgears.co for use in all of your personal design projects. The gearing system is versatile , highly efficient and easy to produce on almost any 3D printer. It is smooth enough to be an excellent bearing , provides plenty of grip as well for gearing, and keeps its functionality under heavy loads.

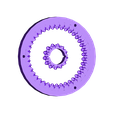

This new gear geometry allows for multiple points of contact arrayed along a curve in space, as compared to standard gears where there is a line of contact arrayed along a surface in space. To understand the efficiency savings, consider that under load , a point transitions to a line, likewise a line transitions to a surface. Assume that each transition requires a factor of 5-100 increase in applied load (based on material) and then the efficiency gains become apparent. This new gear geometry also allows for a great amount of material compression. In other words, the planetary fractal gears can be elastic and operate as an energy return wheel.

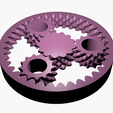

The file available is a complete working unit which you can use out of the printer as a wheel bearing and a 1:4 gear reducer. The fractal gear geometry also allows for alot of fault tolerance on cheaper printers so that high tolerance is not necessary as is the case with every other bearing or gear available today. That allows for combining bearing and gearing means into one unit - a first in engineering, since regular gear designs are not efficient enough to operate as a bearing. So you could for example build a bike wheel which is easily gearable into an electric motor, or build a motorized rotating platform or any other rotating mechanism which may require input power.

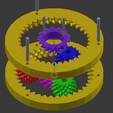

There are multiple files. Each one locks in its assembly to varying degrees. One is better suited as a planetary gear and the other is better suited as a stand alone bearing.There is a file where there are two halves which bolt(or glued, welded, etc) together for a fully enclosed assembly (bearing gears will not come out without disassembly). The two halves can be printed all together as one complete unit, but will need supports for the uppermost fractal gear teeth to form correctly.

Note: Scaling down the model too small may not work on all printers. The smaller the part, the more precise your printer should be. 1/2 scale should work well without extra precision. Any smaller will need a printer which supports a step of .05 mm to be smooth.

This fractal gear bearing design is hypothesized to be an extremely powerful electric bearing motor when made from magnetizable metal, so that hypothetically it can be your motor, bearing, and power transmission in one. That would be achieved by applying a negative charge on the inside gear, and a positive on the outside shell, and giving it a starting spin. Bearing motors have no theoretical explanation for how they work, but are very efficient and powerful. (please see youtube for more information about bearing motors)

This in metal is an extremely powerful electric bearing motor, so that it can simultaneously replace an electric motor, bearing, and power transmission. http://fractalgears.co has available service to print a planetary fractal gears from steel as well for heavy duty applications.

Please remember to have fun. If you have any problems with the files , Let me know. Thanks. This invention is %100 open source so you can use it for whatever you like , including commercially.

Further Reading:

Engineering Principles of Fractal Gears

https://www.academia.edu/s/1f137d62a0/a-fractal-cvt-wheel-bearing-and-electrical-power-generator

Fractal Gear Field Theory

https://www.academia.edu/s/0656dc274f/the-simplest-ever-unified-field-theory

You can read more about fractal gears and fractal gear field theory at www.facebook.com/makeoilworthless.

/https://fbi.cults3d.com/uploaders/13862029/illustration-file/d093f249-ad5f-424f-8e14-e7c0fbf68cb5/untitled.png)