Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

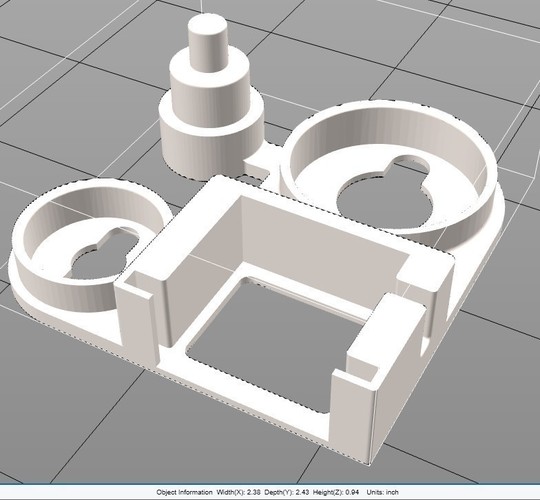

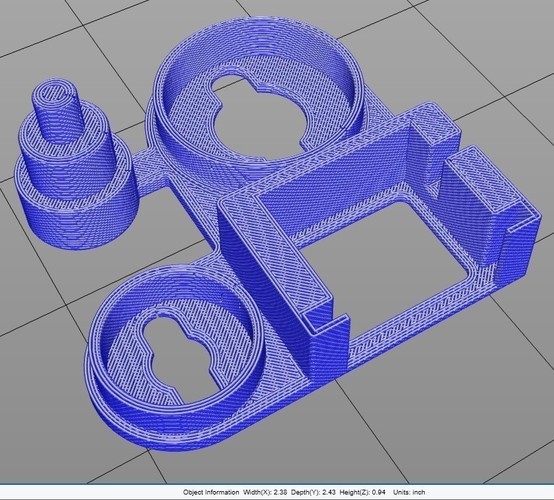

This is a design that I made in order to test-fit some parts and verify that my dimensions for a very large and complex project will work correctly. This test part it designed to fit a Hitec HS-322HD servo... a 1.125" O.D. bearing... and a 0.75" bearing. I printed this object using white PLA from 'Cutequeen' with great results. (200°C extruder and 45°C bed with blue painter's tape; 0.25mm layers; 10% infill; no raft or supports; 1h:10m print time, and consumed 3.43 meters of 1.75mm filament on my da Vinci 1.0 PRO.)

With zero cleaning of the printed part, my servo pushed right into place, quite snugly... as did both ball bearings. In fact, it took quite a bit of force to remove them... which is exactly what I wanted. (Which is why I made openings at the bottom of each part opening, to help push the parts out of their respective positions.) I also created a stepped "tower" of sorts, to test the inside diameters of the bearings. I did not need for them to fit very tightly, and they do not. In fact, they are quite a bit sloppier than I had expected. However, they are more than adequate for the design that I am working on. I find that printing small test objects like this can save a LOT of time printing large objects that will simply never work. Every 3D printer I've owned has been different, so I like to see what they are capable of, and learn their little 'quirks' before printing large, complex parts. (ESPECIALLY if they are parts for an assembly of any kind.) I know that this object won't suit everyone's needs, but it sure suits mine. And it's a large world, out there... I hope it can help someone else, as well. Enjoy!

Comments